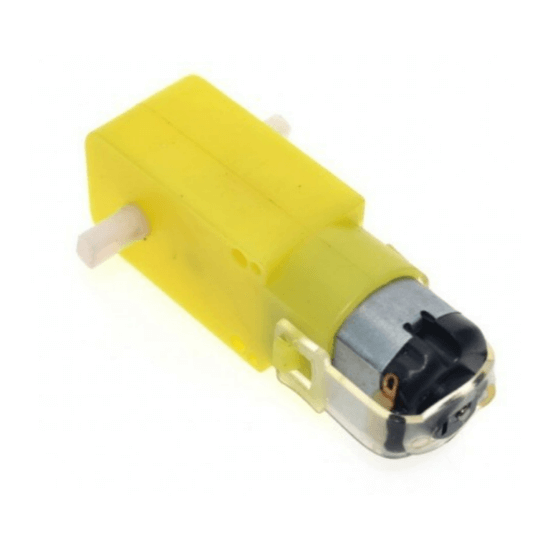

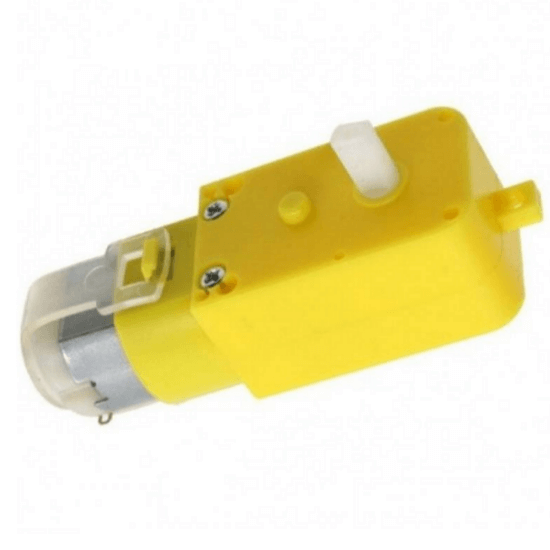

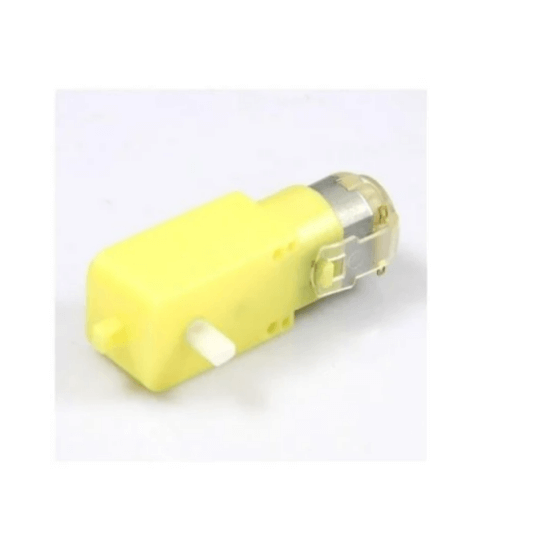

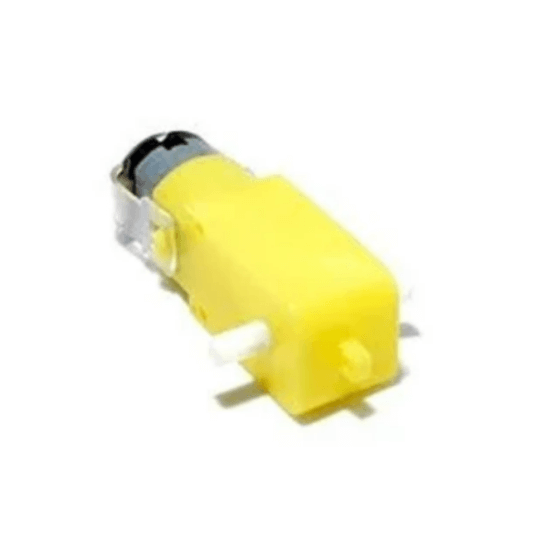

100 RPM Dual Shaft BO Motor-Straight

In stock

- Low density: lightweight, low inertia.

- Capability to absorb shock and vibration as a result of elastic compliance.

- Ability to operate with minimum or no lubrication, due to inherent lubricity.

- The relatively low coefficient of friction.

- Operating Voltage(VDC): 3~12

- Shaft Length (mm): 8.5

- Shaft Diameter (mm): 5.5 (Double D-type)

- No Load Current: 40-180mA.

- Rated Speed(After Reduction): 100 RPM

- Rated Torque: 0.35 Kgcm

₹59.00 ₹89.00 (Price Excl. GST) ₹50.00

In stock

CompareThe 100 RPM Dual Shaft BO Motor Plastic Gear Motor – BO series straight motor gives good torque and rpm at lower operating voltages, which is the biggest advantage of these motors. A small shaft with matching wheels gives an optimized design for your application or robot. Mounting holes on the body & light weight make it suitable for in-circuit placement. This motor can be used with a 69mm Diameter Wheel for Plastic Gear Motors and an 87mm Diameter Multipurpose Wheel for Plastic Gear Motors.

Low-cost geared DC Motor. It is an alternative to our metal gear to make DC motors. It comes with an operating voltage of 3-12V and is perfect for building small and medium robots. Available with 60 and 150 RPM. The motor is ideal for DIY enthusiasts. This motor set is inexpensive, small, easy to install, and ideally suited for use in a mobile robot car. They are commonly used in our 2WD platforms. We are supplying the range BO(Battery Operated) Motors with varying RPM and Gear-Box arrangement, click on the name below for more information.

The 100 RPM dual shaft BO (Brushed DC) motor operating at a straight rotational speed of 100 revolutions per minute (RPM) represents a versatile and powerful component in robotics, automation, and various mechanical systems. With dual shafts, this motor offers enhanced functionality and flexibility, making it suitable for a wide range of applications that require precise control and reliable performance.

Operating at a rotational speed of 100 RPM, this motor strikes a balance between speed and torque, providing sufficient rotational velocity to drive mechanical systems while delivering the necessary power to overcome resistance and inertia. This makes it ideal for tasks such as conveyor belt control, robotic arm movement, and precision positioning applications where both speed and torque are crucial for optimal performance.

The dual shaft configuration of the motor further enhances its versatility by providing two output shafts, each capable of independently driving mechanisms or components. This allows engineers and designers to implement complex motion control schemes, such as differential steering in mobile robots or multi-axis manipulation in robotic arms, with ease and precision. The dual shaft design also enables the motor to perform multiple tasks simultaneously, maximizing efficiency and productivity in various applications.

The brushed DC motor design employed in this motor ensures reliability and durability, making it suitable for continuous operation in demanding environments. The presence of brushes and a commutator allows for straightforward control of motor speed and direction, while also providing robust electrical connections that minimize the risk of signal loss or interference. This simplicity of design, coupled with the motor’s rugged construction, ensures long-term performance and reliability in industrial, commercial, and academic settings.

The versatility of the 100 RPM dual shaft BO motor extends beyond its performance characteristics to its ease of integration and compatibility with existing systems. The motor’s standardized dimensions and mounting options facilitate seamless installation in a variety of applications, while its compatibility with commonly used motor controllers and power sources simplifies the process of incorporating it into new or existing projects. Additionally, the motor’s dual shafts allow for direct coupling to a wide range of mechanisms, reducing the need for additional gearing or transmission components and streamlining the overall design.

In conclusion, the 100 RPM dual shaft BO motor operating at a straight rotational speed of 100 RPM offers a powerful and versatile solution for robotics, automation, and mechanical systems. With its balance of speed and torque, rugged brushed DC design, and dual shaft configuration, this motor provides the performance and flexibility needed to drive innovation and efficiency in a variety of applications.

BO Motors

Note: These Motors are available in three different colors i.e. Yellow, Black, and white, we will ship it randomly.

Features :

- Cost-effectiveness of the injection-molding process.

- Elimination of machining operations.

- Low density: lightweight, low inertia.

- Uniformity of parts.

- Capability to absorb shock and vibration as a result of elastic compliance.

- Ability to operate with minimum or no lubrication, due to inherent lubricity.

- The relatively low coefficient of friction.

- Corrosion-resistance; elimination of plating, or protective coatings.

- The quietness of operation.

- Tolerances often less critical than for metal gears, due in part to their greater resilience.

- Consistency with the trend to greater use of plastic housings and other components.

Package Includes :

1 x 100 RPM Dual Shaft BO Motor – Straight

Specifications

| Operating Voltage (VDC) | 3 ~ 12 |

| Shaft Length (mm) | 8.5 |

| Shaft Diameter (mm) | (Double D-type) 5.5 |

| No Load Current (mA) | 40-180mA. |

| Rated Speed After Reduction (RPM) | 100 |

| Rated Torque (Kg-Cm) | 0.35 |

| Weight (gm) | 30 |

| Dimensions in mm (LxWxH) | 70 x 23 x 19 |

| Gearbox Shape | Straight |

| Shipment Weight | 0.033 kg |

Shipping & Returns

Due to the type of products we sell, we accept limited returns. Below are the conditions where we can accept a return request.

MANUFACTURING DEFECT

If you receive a product with a manufacturing defect, please notify us within 1 day of receiving the product, supported by the proper pictures and description. Once our support team accept the return, we will provide a replacement or a complete refund including the return shipping cost.

WRONG ITEM SHIPPED

If you receive a different product than the ordered one, please contact us within 1 day of receiving the product, supported by the proper pictures and description. Once our support team accept the return, we will provide a replacement or a complete refund including the return shipping cost.

LIMITATION OF RETURNS

We don’t accept returns for products damaged by improper use of the product. Moreover, we don’t accept the return if the ordered product is unsuitable for any specific application. Please read the product specifications and datasheet before selecting and ordering a product.

WHAT VOID WARRANTY?

If the product is subject to misuse, tampering, static discharge, accident, water or fire damage, use of chemicals & soldered or altered in any way.

SHIPPING

We ship all over India. Please contact our support team at info@inventkart.com for any questions related to shipping.

Based on 0 reviews

Be the first to review “100 RPM Dual Shaft BO Motor-Straight”

You must be logged in to post a review.

There are no reviews yet.