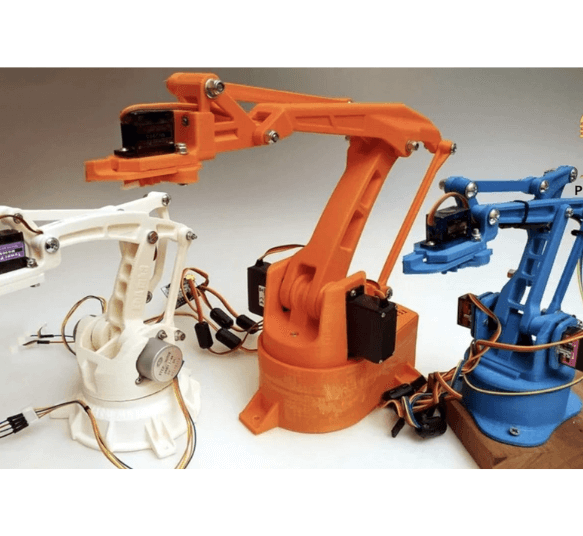

Robotic Arm 3D Printed Parts with Nuts and Bolts (Without Servo)

In stock

- DIY Robotic Arm KIT.

- All nuts and bolts available.

- Printed with PLA Pro Special Filament.

- Compatible with Arduino.

- Servos and controller Not Included.

₹550.00 ₹1,999.00 (Price Excl. GST) ₹466.10

In stock

3D printing technology has revolutionized manufacturing across industries, offering unprecedented flexibility and customization. Among its myriad applications, the creation of robotic arm components stands out as a prime example of its versatility. Leveraging the additive manufacturing process, engineers and enthusiasts alike can design and fabricate intricate parts with intricate geometries, tailored precisely to the needs of the robotic arm’s functionality.

At the heart of this innovation lies the fusion of 3D-printed parts with traditional nuts and bolts. While 3D printing enables the production of complex shapes and structures with relative ease, incorporating nuts and bolts adds a layer of mechanical robustness and versatility. This hybrid approach combines the best of both worlds: the agility of additive manufacturing and the reliability of conventional fastening mechanisms.

The marriage of 3D-printed parts with nuts and bolts begins with meticulous design considerations. Engineers meticulously craft digital models, optimizing geometries for strength, weight, and functionality. This design phase is crucial, as it determines the success and efficiency of the final robotic arm assembly. Every curve, every angle, and every cavity is meticulously planned to ensure seamless integration with nuts and bolts.

Once the design is finalized, the 3D printing process commences. Layer by layer, the printer deposits molten plastic, gradually materializing the envisioned components. Depending on the specific requirements of the robotic arm, various types of 3D printing techniques may be employed, ranging from fused deposition modeling (FDM) to stereolithography (SLA), each offering its unique advantages in terms of resolution, speed, and material compatibility.

With the 3D printed parts in hand, attention turns to the integration of nuts and bolts. This step requires precision and care to ensure proper alignment and secure fastening. Nuts are carefully embedded within designated recesses or channels within the 3D printed components, providing anchor points for bolts to thread into. Alternatively, captive nuts can be inserted post-printing, offering flexibility in assembly and disassembly.

Bolts, selected for their size, strength, and compatibility with the printed material, are then inserted through designated holes in the 3D printed parts. As they thread into the embedded nuts, a mechanical bond is formed, securely joining the components together. Tightening the bolts to the appropriate torque ensures optimal clamping force, preventing loosening or failure during operation.

The integration of nuts and bolts introduces modularity and serviceability to the robotic arm assembly. In the event of damage or wear, individual components can be easily replaced without the need for complex retooling or re-printing of entire assemblies. This modularity not only streamlines maintenance but also facilitates iterative improvements and upgrades, ensuring the robotic arm remains adaptable to evolving requirements.

Moreover, the combination of 3D printed parts with nuts and bolts offers scalability and cost-effectiveness. Prototyping and small-scale production can be rapidly executed using additive manufacturing techniques, minimizing lead times and upfront costs. Meanwhile, standardized nuts and bolts, readily available in hardware stores worldwide, ensure accessibility and affordability, further lowering barriers to entry for enthusiasts and professionals alike.

In conclusion, the integration of 3D printed parts with nuts and bolts represents a symbiotic relationship between cutting-edge technology and time-tested engineering principles. This hybrid approach unlocks new possibilities in robotic arm design, combining the flexibility of additive manufacturing with the reliability of traditional fastening mechanisms. As additive manufacturing continues to advance, propelled by innovations in materials and processes, the synergy with nuts and bolts will undoubtedly play a pivotal role in shaping the future of robotics.

The Robotic Arm with Gripper DIY Kit, which includes all nuts and bolts (Servos and controller not included), is a versatile platform for enthusiasts and learners alike:

Specifications

- Customizable Design: This kit offers flexibility because it allows you to customize the robotic arm according to your specific needs and preferences.

- STEM Learning: Ideal for educational purposes, it helps users gain valuable STEM skills through hands-on assembly and programming.

- Endless Creativity: Because of its open-source nature, you can explore endless possibilities for robotics projects and innovations.

- Enhanced Problem-Solving: Building and programming the robotic arm improves problem-solving skills, making it a valuable educational tool.

- Versatile Applications: This kit is adaptable for various applications, including automation, pick-and-place tasks, and experimentation.

- Solid Construction: The included nuts and bolts ensure a robust and stable build for your robotic arm.

- Affordable Learning: It’s cost-effective, offering an affordable way to learn and experiment with robotics.

- Expandable: Additionally, you can expand its capabilities by adding servos and a controller, enhancing its functionality.

- Innovation Potential: With creativity and additional components, you can transform this kit into a versatile robotic system.

- DIY Fun: Lastly, it provides an enjoyable DIY experience for hobbyists and learners, fostering a sense of accomplishment* Product Images are shown for illustrative purposes only and may differ from actual product.

Packages includes:-

- 1 x Robotic Arm With Gripper Diy Kit ( All Nuts & Bolts Included, Servos and controller Not Included)

Specifications

- DIY Robotic Arm KIT.

- All nuts and bolts available.

- Printed with PLA Pro Special Filament.

- Compatible with Arduino.

- Servos and controller Not Included.

Shipping & Returns

Due to the type of products we sell, we accept limited returns. Below are the conditions where we can accept a return request.

MANUFACTURING DEFECT

If you receive a product with a manufacturing defect, please notify us within 1 day of receiving the product, supported by the proper pictures and description. Once our support team accept the return, we will provide a replacement or a complete refund including the return shipping cost.

WRONG ITEM SHIPPED

If you receive a different product than the ordered one, please contact us within 1 day of receiving the product, supported by the proper pictures and description. Once our support team accept the return, we will provide a replacement or a complete refund including the return shipping cost.

LIMITATION OF RETURNS

We don’t accept returns for products damaged by improper use of the product. Moreover, we don’t accept the return if the ordered product is unsuitable for any specific application. Please read the product specifications and datasheet before selecting and ordering a product.

WHAT VOID WARRANTY?

If the product is subject to misuse, tampering, static discharge, accident, water or fire damage, use of chemicals & soldered or altered in any way.

SHIPPING

We ship all over India. Please contact our support team at info@inventkart.com for any questions related to shipping.

Based on 0 reviews

Be the first to review “Robotic Arm 3D Printed Parts with Nuts and Bolts (Without Servo)”

You must be logged in to post a review.

You may also like…

-

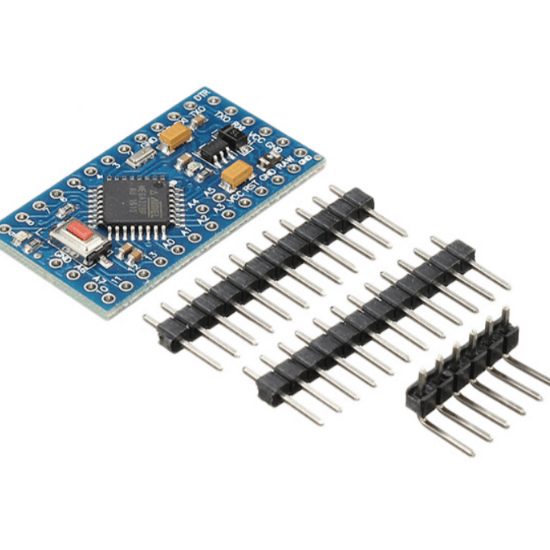

All Products, Arduino Boards

Arduino Nano R3 Compatible Board with CH340 chip(Unsoldered)

- Operating Voltage (logic level): 5V

- With Soldered Connector

- 8 analog inputs ports: A0 ~ A7

- 14 Digital input / output ports: TX, RX, D2 ~ D13

- 1 pair of TTL level serial transceiver ports RX / TX

- Using Atmel Atmega328P-AU MCU

- There is a bootloader installed in it

- Standard 0.1” spacing DIP (breadboard friendly).

- Manual reset switch.

SKU: IK-115 -

All Products, Stepper Motor/ Controller

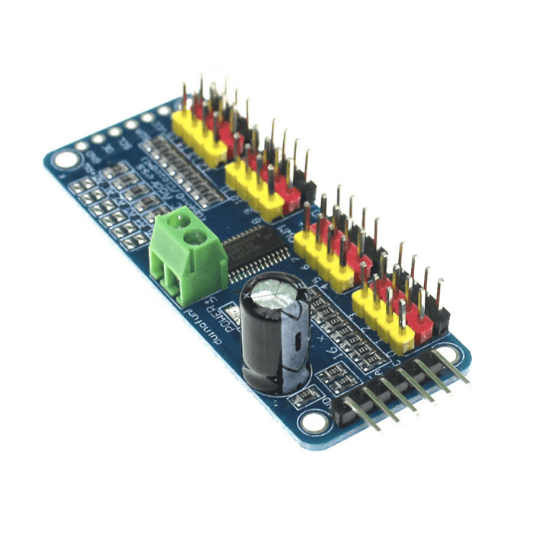

16-Channel 12-bit PWM/Servo Driver I2C interface PCA9685 for Arduino Raspberry Pi

All Products, Stepper Motor/ Controller

All Products, Stepper Motor/ Controller16-Channel 12-bit PWM/Servo Driver I2C interface PCA9685 for Arduino Raspberry Pi

- Adjustable frequency PWM up to about 1.6 KHz

- 12-bit resolution for each output – for servos, that means about 4us resolution at a 60Hz update rate

- Configurable push-pull or an open-drain output

- The output enable pin to quickly disable all the outputs

- Terminal block for power input

- Reverse polarity protection on the terminal block input

- Green power-good LED

SKU: IK-127

There are no reviews yet.